Electric infrared curing and drying heaters are twice as fast, more efficient and smaller than traditional gas convection ovens. But there’s another critical reason curers are turning off their gas convection ovens and turning to electric IR: bad chemistry.

Gas ovens worked fine for a century because most coatings and paints were solvent-based. All the curers needed was fairly hot air — up to 1,000 degrees — to circulate and cure paint off the workpieces. The solvents vaporized, often producing plenty of toxic VOC, and cured the workpieces evenly.

Today, solvent-based coatings and paints are disappearing. Virtually all modern coating paints are either water-based organic coatings or newer spray-on, electrostatic powders. They have one thing in common: gas convection ovens cannot cure them properly.

- They can’t generate enough heat to bind the coatings and substrates.

- They don’t have the precision to optimize coating quality.

- Swirling hot air and emissions cause power blowback or discolored coatings.

- When it comes to water bases and power, they’re simply on the wrong wavelength.

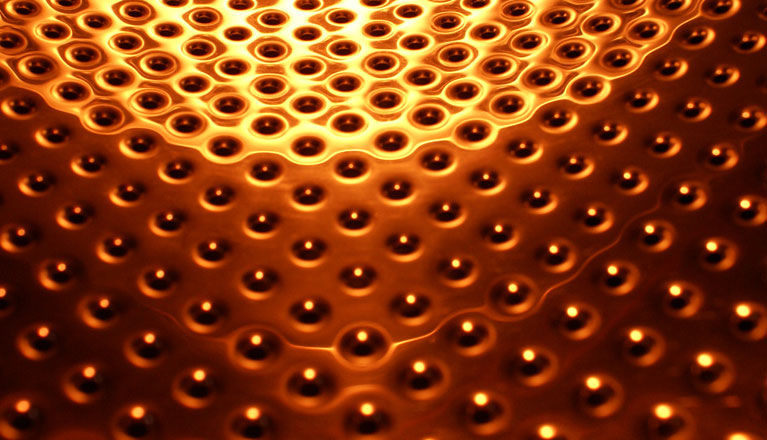

Electric IR heaters can produce radiation energy across the entire infrared spectrum at precisely controlled wavelengths, frequencies and temperatures. As noted in ScienceDirect, this range and control vastly improve the quality of organic coatings, providing “precise control of color, gloss, texture and surface finish,” and also improve the performance of finished coatings in the outside world. The key is matching exactly the right wavelength to the absorption characteristics of the coating: instead of heating and air and baking the parts, IR heats the coating and the substrate directly which improves the overall thermal efficiency. An electric IR heater can endlessly maintain a temperature within one degree of the ideal wavelength and temperature, day in and day out, to precisely heat, dry and cure modern organic coatings.

Electric IR heating is especially well-suited to cure and dry water-based coatings, which are formulated to cure and dry at medium wavelengths set to water’s absorption bands, instead of having the water boiled away in the hot air of a gas convection oven. Result: a high-quality coating that eliminates VOC emissions.

Modern powder coatings are becoming increasingly popular, melting and binding into finished coatings with exceptional durability — resistant to chipping, scratching, fading and wearing. They’re designed specifically for electric IR curing because gas convection ovens simply can’t produce the thermal intensity needed to cure them. And, you don’t want the swirling air of a convection oven blowing off powder and landing on every surface in the plant, or infiltrating into the oven’s airstream to contaminate and discolor other products. Electric IR heaters don’t heat air; they heat powder, at exactly the wavelength and temperature the manufacturer specifies.